Some Ideas on Roar Solutions You Need To Know

( Area 0, 1, or 2). This variation will certainly likewise affect the resourcing needs for job preparation. When Great deals are specified, you can develop sampling plans based on the sample size of each Great deal, which refers to the number of random devices products to be checked. To determine the required sample size, two elements need to be examined: the dimension of the Whole lot and the category of examination, which indicates the level of effort that must be used( decreased, regular, or enhanced )to the evaluation of the Great deal. By integrating the classification of assessment with the Great deal size, you can then develop the ideal being rejected standards for an example, meaning the allowed variety of malfunctioning products found within that sample. For even more details on this procedure, please describe the Energy Institute Standards. The IEC 60079 basic recommends that the optimum period between inspections should not go beyond 3 years. EEHA evaluations will additionally be carried out outside of RBI projects as component of scheduled maintenance and equipment overhauls or fixings. These assessments can be credited towards the RBI sample dimensions within the impacted Great deals. EEHA inspections are carried out to determine mistakes in electrical equipment. A heavy scoring system is crucial, as a single tool may have multiple mistakes, each with varying degrees of ignition risk. If the consolidated rating of both examinations is less than two times the fault rating, the Lot is considered appropriate. If the Lot is still taken into consideration undesirable, it must undertake a full examination or justification, which might set off more stringent evaluation methods. Accepted Lot: The root causes of any kind of faults are determined. If an usual failure mode is located, additional equipment might call for evaluation and fixing. Faults are categorized by severity( Safety, Stability, Housekeeping ), guaranteeing that immediate concerns are evaluated and attended to without delay to mitigate any type of effect on safety and security or operations. The EEHA database must track and tape-record the lifecycle of faults in addition to the rehabilitative actions taken. Carrying out a durable Risk-Based Examination( RBI )strategy is important for making certain conformity and safety and security in managing Electrical Equipment in Hazardous Areas( EEHA). Automated Fault Scoring and Lifecycle Monitoring: Easily manage faults and track their lifecycle to enhance evaluation accuracy. The introduction of this support for risk-based examination even more enhances Inspectivity's placement as a best-in-class solution for regulatory compliance, as well as for any asset-centric inspection use instance. If you are interested in learning more, we welcome you to request a demonstration and discover how our remedy can change your EEHA administration processes.

With over 10 years of consolidated Ex experience (IECEx/ATEX, EEHA), Saipex began to advertise the value of competence of all workers associated with the Hazardous Location area in 2019. In 2021, our partnership with IndEx and Technology Skill International (TSI) marked a landmark in the Saipex road to proceed Ex-spouse enhancement.

The smart Trick of Roar Solutions That Nobody is Discussing

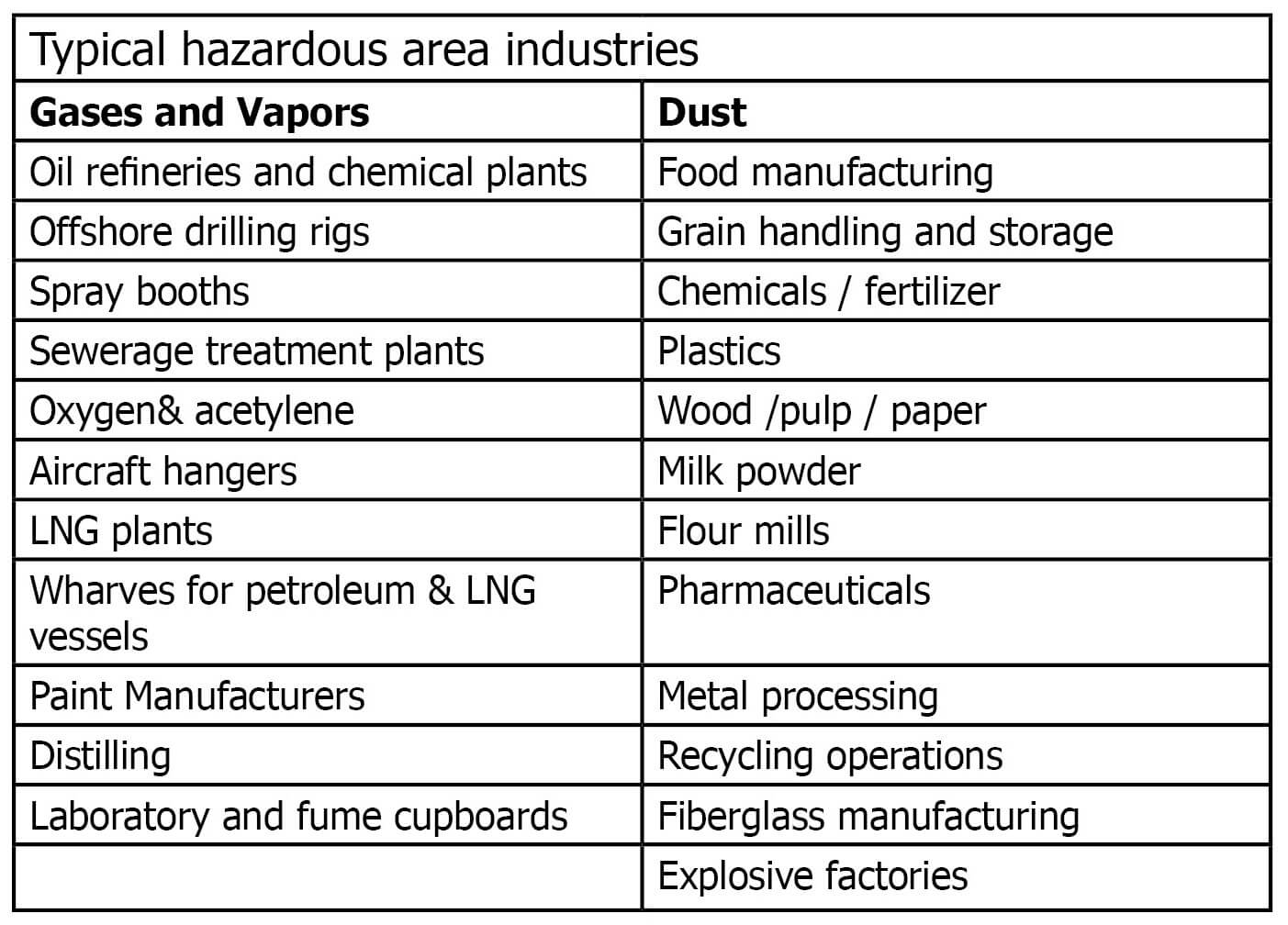

In terms of explosive danger, a hazardous area is an atmosphere in which an eruptive atmosphere is present (or might be anticipated to be existing) in amounts that require special safety measures for the construction, setup and usage of tools. In this write-up we explore the difficulties dealt with in the office, the threat control actions, and the required competencies to work safely.

These substances can, in specific problems, create explosive atmospheres and these can have significant and unfortunate repercussions. Many of us are acquainted with the fire triangular remove any type of one of the 3 components and the fire can not occur, however what does this mean in the context of unsafe locations?

This is then confirmed through examination and testing and is maintained throughout the life of the installation by using the appropriate upkeep techniques, supplemented by regular inspection. When all these procedures are taken, they should likewise be recorded. The confirmation dossier consists of details such as the dangerous location category drawing, makers' documentation, devices qualification, design drawings and estimations, inspection documents, and documents of a person's competency and continuing specialist growth (CPD), such as by means of ECA's eCOMS software.

Roar Solutions Fundamentals Explained

It is crucial that students comprehend and have a comprehensive expertise as to just what comprises a dangerous location. The pupil should likewise understand why training is essential before attempting to tackle work or specifying equipment into a harmful location. These locations are additionally called categorized places and are specified as locations which have a high possibility of an explosion since of the possible existence of flammable gases, vapors, dusts etc.

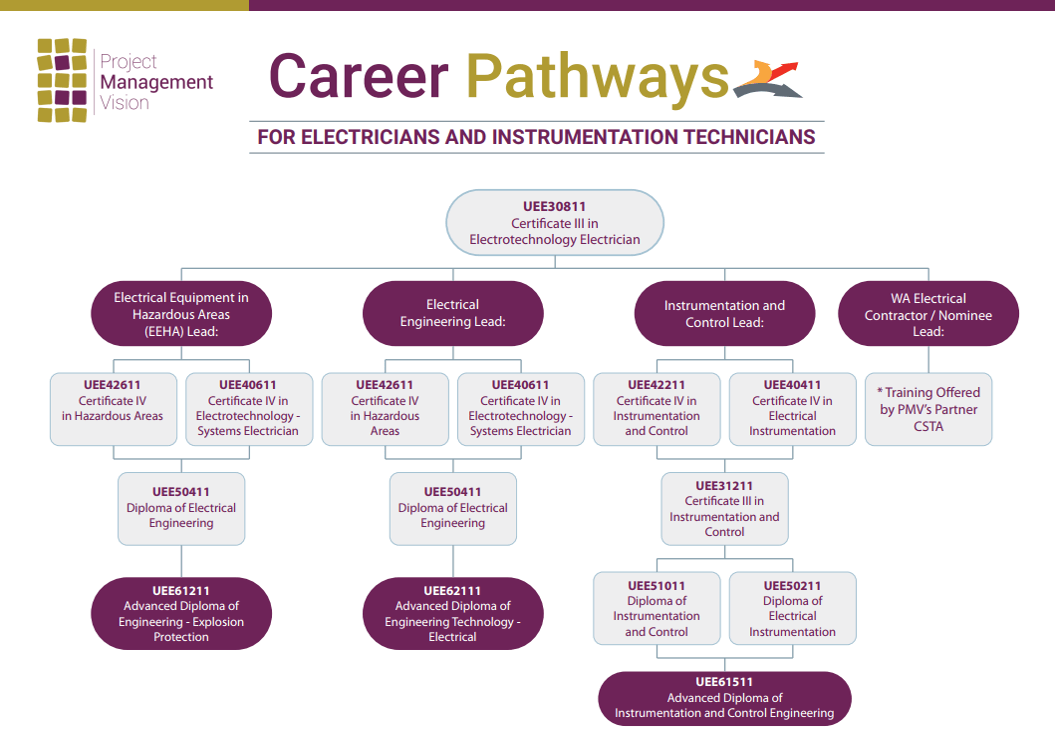

Industries that include harmful areas are now demanding that electrical workers that are specifying or operating in these areas should have a dangerous area certification that considers them experienced. Jobs in these sectors are really fulfilling so you require to be prepared. To fulfill this need for the market, country wide identified training in Certification IV in Harmful location Electrical and EEHA training on the advancement of knowledgeable specialists.

What Does Roar Solutions Do?

Technology Abilities Australia is a Registered Training Company giving you with one of the most economical and quickest method in acquiring your credentials - eeha certificate. Our trainers are market qualified and have several years of process experience. Our courses have actually helped hundreds of people from corporate supervisors to day-to-day staff members in getting a strong hold on this not so complex but high risk training

The training additionally consists of determining the harmful areas, sources of surge and the residential or commercial properties of dangerous materials in addition to the duties and features of all celebrations, policies, systems, requirements and practice codes connected to hazardous locations. We give instrumentation and unsafe location remedies that remain in conformity to most current AS/NZS and international industry standards.

Comments on “Roar Solutions Things To Know Before You Buy”